California’s Allfast Fastening Systems, a division of TriMas Aerospace, is a leading worldwide supplier of solid and blind rivets, blind bolts, and installation tooling to the aerospace industry. Holding a plane fuselage together takes tens of thousands of rivets; if you’re flying on an aircraft built by Boeing, Airbus, Embraer, or Bombardier, chances are that the rivets you see when you board were made by Allfast.

Allfast prides itself on its reputation for manufacturing precision, and it has long used technologically advanced processes such as CNC [Computer Numerical Control] machining to make products of unrivaled quality. Allfast’s industry customers have routinely recognized the company with accolades such as the Boeing President’s Award for Supplier of the Year.

The Problem: Understanding Operational Effectiveness with an Error-Prone Paper Process

Until 2020, however, Allfast was using an entirely manual process for internal reporting of labor and machine usage. When an Allfast specialist would receive a work order from planning, they would need to manually enter the clock-in time and type of operation performed for each machine used in the manufacturing process. When finished, the same practice applied for clock-out time—along with manually recording the number of units manufactured once the work order was completed.

This cumbersome process required supervisors to keep track of reams of paper generated by over 100 specialists working on a similar number of machines. Supervisors needed to scan the information from each timesheet and then enter it into an Excel file, with Excel’s outputs uploaded periodically into the company’s ERP by Human Resources. As TriMas Information Technology Director Carlos Contreras puts it, “It was almost impossible for supervisors to know the previous day’s utilization—in the best case, you might know Monday’s utilization by Friday.”

Even this “best-case” scenario was hard to realize, however, because of the greater problem of imprecision: The process was woefully error-prone, and correcting the errors consumed supervisors’ time each month—time spent deciphering handwriting, tracking down operators, and reconciling contradictory information. The cost to Allfast wasn’t only incurred in wasted hours; it was also felt in the company’s inability to maneuver quickly—or with accurate figures—to maximize utilization and absorption or manage overtime efficiently.

“At the end of all that,” says Contreras, “our utilization figures were still kind of a best guess. We knew we had to fix this.”

The Solution: Automation with TracerPlus

Given that the problem centered around manufacturing efficiency and effectiveness, Allfast initially asked its ERP provider to build an interface that would automate the process. After receiving a quote, along with the information that it would take at least six months to put a beta version in place, Contreras decided to take matters into his own hands by reaching out to Portable Technology Solutions and their TracerPlus mobile application/form-designer software for barcode and RFID readers. Traditionally, many barcode and RFID solutions are utilized to track sales or the movements of goods and services. Contreras needed to capture and correlate data for labor, workstations, and equipment—and align this to the manufacturing-associated work orders. “I had used TracerPlus in a previous job,” Contreras says, “so I knew how easy it is to build applications.”

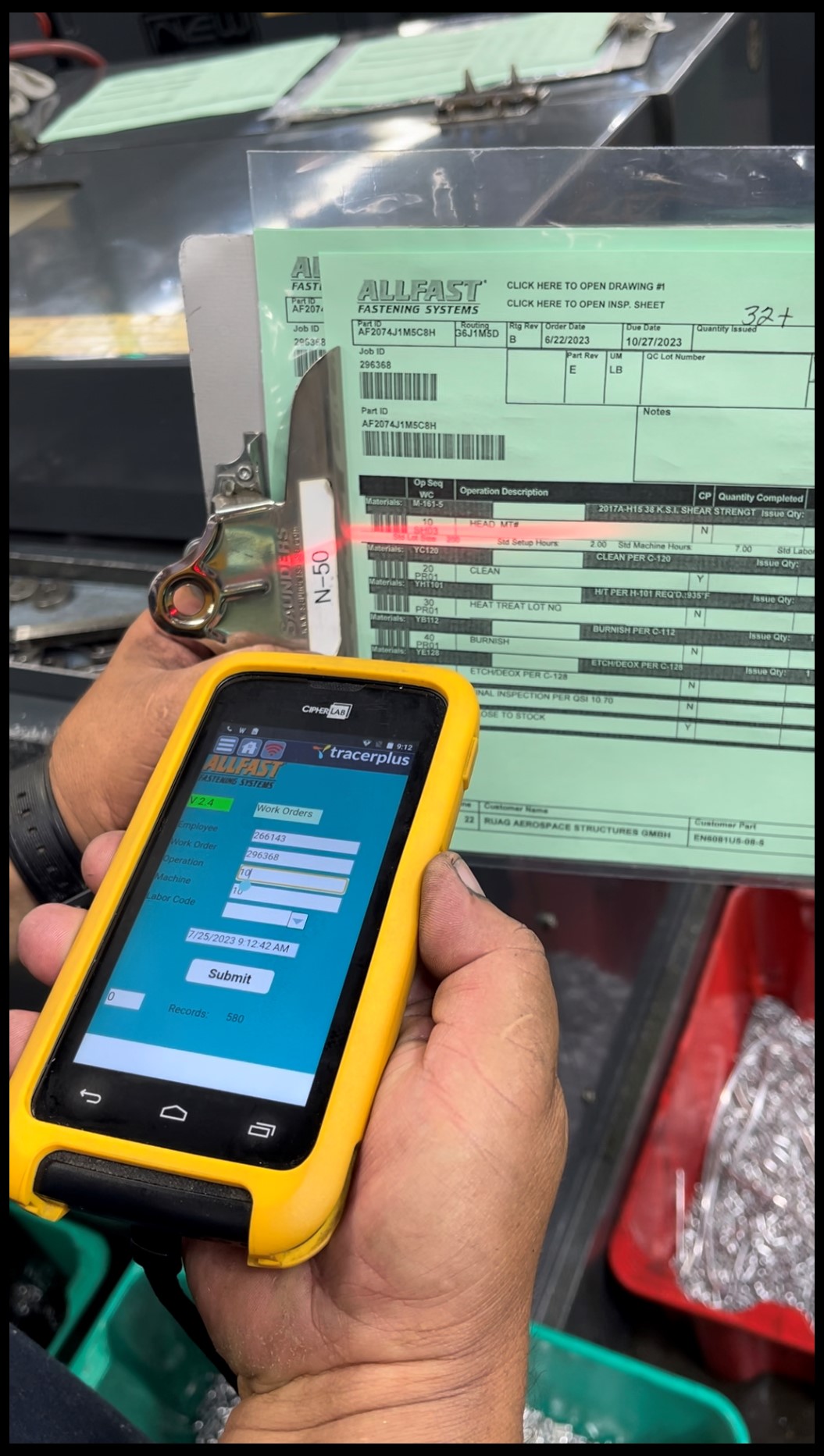

Contreras decided to use a barcode-enabled system to capture the multiple data elements within the associated manufacturing workflows. Implementation of a completely automated solution to replace the previous manual process took little more than a month from conception to execution. Operators were issued barcoded badges and were equipped with Cipherlab RS35 mobile barcode scanners loaded with the TracerPlus-built sessions. “We created three operations initially,” Contreras recalls, “one to clock in, one to clock out, and a third for supervisors to make adjustments.”

Now an operator logs in with the employee badge and, with all the work orders printed in a barcode, they simply use the first session built in TracerPlus to scan the work order, scan the code for the particular operation and machine, and press “submit” to clock in. To clock out, they use the second session, which displays all the operator’s work orders from that day: they select the work order from which they want to clock out, and hit “submit.”

A process that formerly took weeks to produce actionable information is now handled in real-time, with a database connection for a dashboard handled by Microsoft Power BI, along with a process to load the same information into the ERP. Since the initial implementation, Allfast has built five additional applications in TracerPlus to enable supervisors to also track indirect operations and perform timing analysis on the tooling department—information that wasn’t available at all previously.

Information is now not only available in real time—it’s also, most importantly, accurate and reliable.

Return on Investment: Direct and Indirect Benefits

The accurate, real-time information that Allfast gleaned from using TracerPlus was immediately eye-opening, allowing the company to increase utilization from 78% to 83% in only six months.

Three years into using the new TracerPlus-enabled clock-in/clock-out system, utilization now stands at a 90 percent average per month.

This measurable improvement in utilization—and a corresponding increase in absorption—was partially due to the increased accountability introduced by the new system. It was also the result of finally having a reliable stream of timely, accurate, and precise data on which to base planning decisions.

After only six months with the new system, the data revealed a number of operational inefficiencies, which supervisors addressed by instituting changes in the work-floor layout and in how work orders were distributed among the specialists.

On the labor and payroll side, the allocation of hours—at the supervisor pay scale—to correct the errors inherent in the manual system has been eliminated. What’s more, specialists’ overtime claims have decreased dramatically; a volume of claims that was once routine is now only seen when there are specific manufacturing contingencies. Three years into using TracerPlus, “there is really no comparison” with the old, manual system, Contreras says. “We’re able to do real, data-driven analysis now; before, it was guesswork. What we have now is accurate and it is accessible in real-time. And when you have real-time information, you can address problems as they occur. In addition to all the quantifiable benefits that TracerPlus has helped bring about, that is, in itself, is a soft benefit.”